Ductile Iron Pipes in Oil Sphere

Due to high staying quality and corrosive resistance ductile iron pipes find their use in the gas and oil sphere. Ductile iron pipes have a successful usage experience as pipelines pumping the most polluted and aggressive fluid that is oil containing products (conglomerate products, formation waters, hydrogen disulfide, carbon dioxide, paraffine oil and solid particles) from oil wells.

Ductile iron pipelines and some pipeline sectors are applied in oilfields of oil Company Rosneft (JuganskNefteGaz, Arlanneft, Purneftegaz, Samaraneftegaz, Samotlorneftegaz, Nizhnevartovsk, Udmurtneft), JSC Lukoil (Lukoil-Perm, Lukoil-AIK).

The experience of ductile iron pipe usage in oil sphere showed that the main estimated service figure is that the corrosive resistance is 4-10 times higher than of steel pipes. Together with special covering like high-alumina cement, polymer this estimated figure can increase many times.

Together with special covering like high-alumina cement, polymer this estimated figure can increase many times.

|

Ductile iron pipeline in oil sphere is applied with the socket-spigot connection “RJ”. This type of joint connection is used when a pipe has a straight end from one side and the socket from another. During the as-sembling process the straight end goes to the socket and fixes with the left and the right anchors. Leak-proofness is obtained by set-ting rubber gasket ring. Rubber gasket rings are made of combination of hydrogenated butadiene-acrylonitrile rubber that is resistant to oil well products. |

|

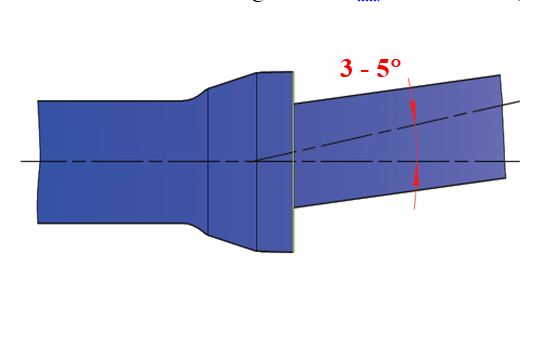

Socket-straight end connection provides impossibility of pipe disconnection during pipe service process and allows work in unstable soil conditions, rugged relieves, load impact and allows refuse concrete stops. The type of connection is proved to provide pipeline leak-proofness and failure re-sistance in a range from 2,5 to 4,0 MPa (depending on diameter) having an ample margin. Socket-straight end connection is not rigid and allows having an angular deflection up to 5 degrees depending on pipe diameter providing a full leak-proofness of the joint. It allows make big radius turns, correct pipeline route without using special fittings.

|

|

Norms and specifications for design process and ductile iron pipeline RJ joint in oil sphere.

|

|

Technical specifications 1464-075-50254094-2012Socket-spigot “RJ” joint pipes from ductile iron for infield pipelining at oilfields

|

|

|

Technical specifications 1461-076-50254094-2012Cast fittings with socket-spigot “RJ” joint from ductile iron for infield pipelining at oilfields

|

|

|

Technical specifications 1461-077-50254094-2011Rubber gaskets for infield ductile iron “RJ” joint pipelining at oilfields

|

|

|

Technical specifications 1461-078-50254094-2012Welded fittings with socket-spigot “RJ” joint from ductile iron for infield pipelining at oilfields

|

|

|

|

|

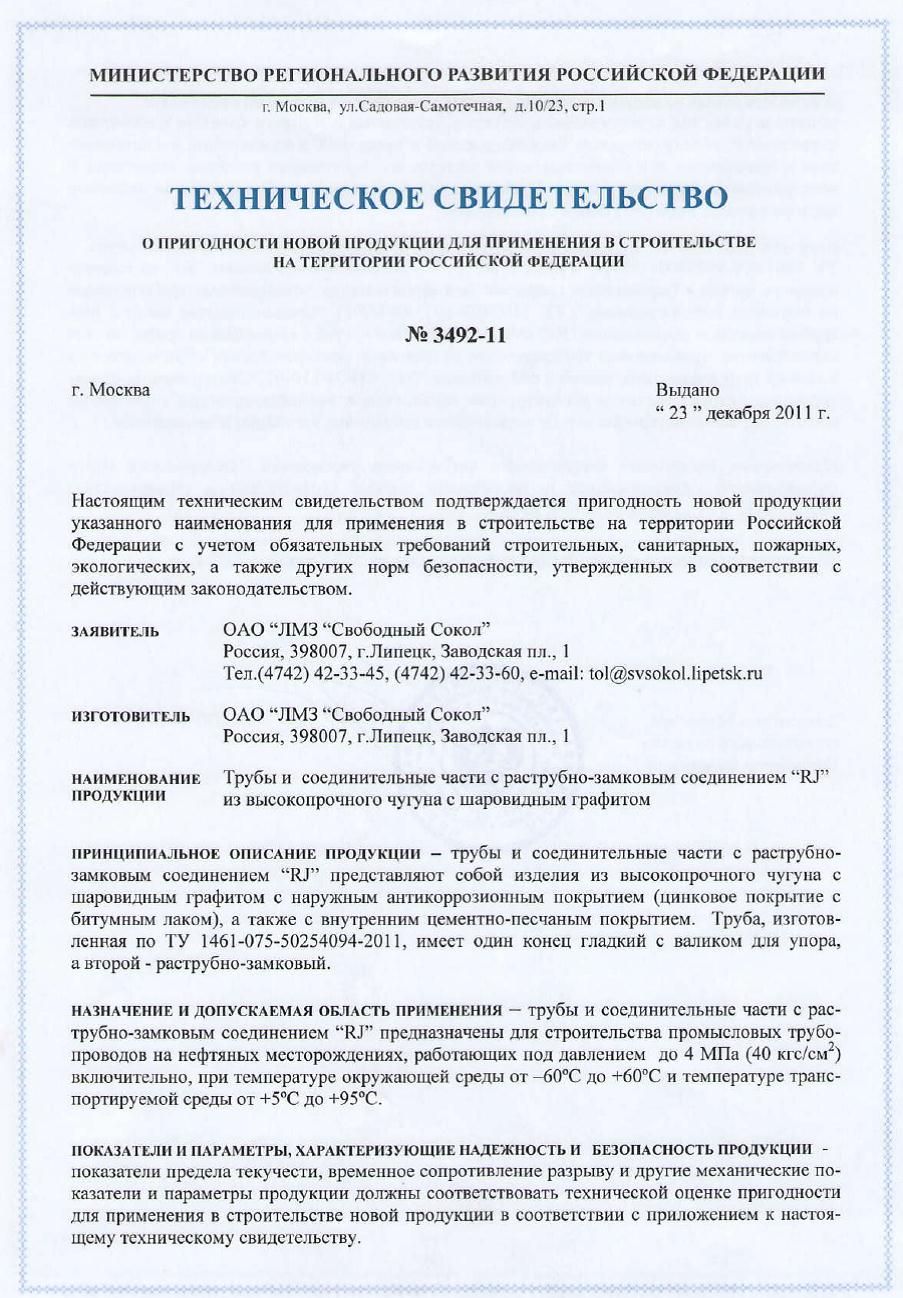

Technical license for Socket-spigot “RJ” joint pipes from ductile iron for infield pipelining at oilfields on the territory of Russian Federation. |

For the most severe circumstances of service and for long working service prolongation we suggest using high-alumina cement on the inner side of the pipes and fittings.

This covering has an increased resistance to abrasion, a high resistance to oil products, hydrogen disulfide and carbon dioxide.

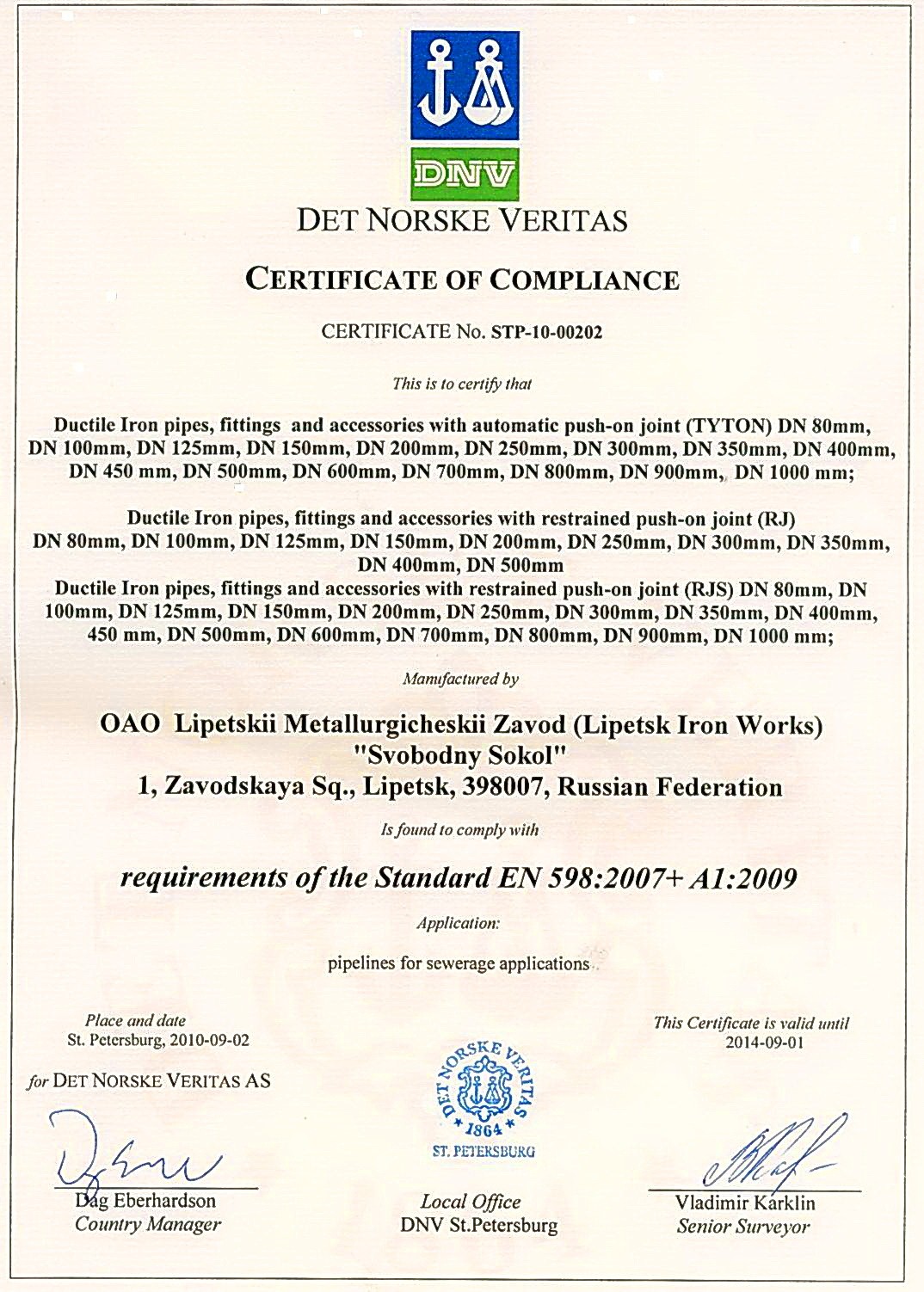

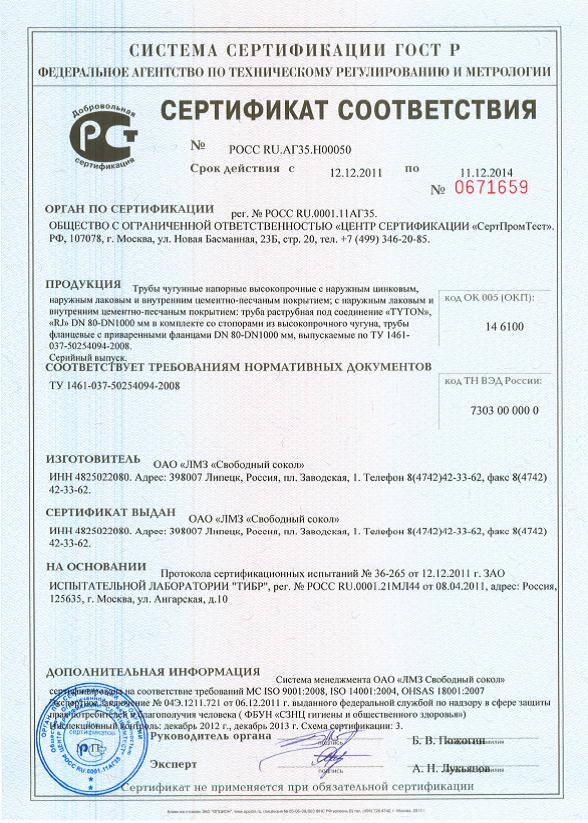

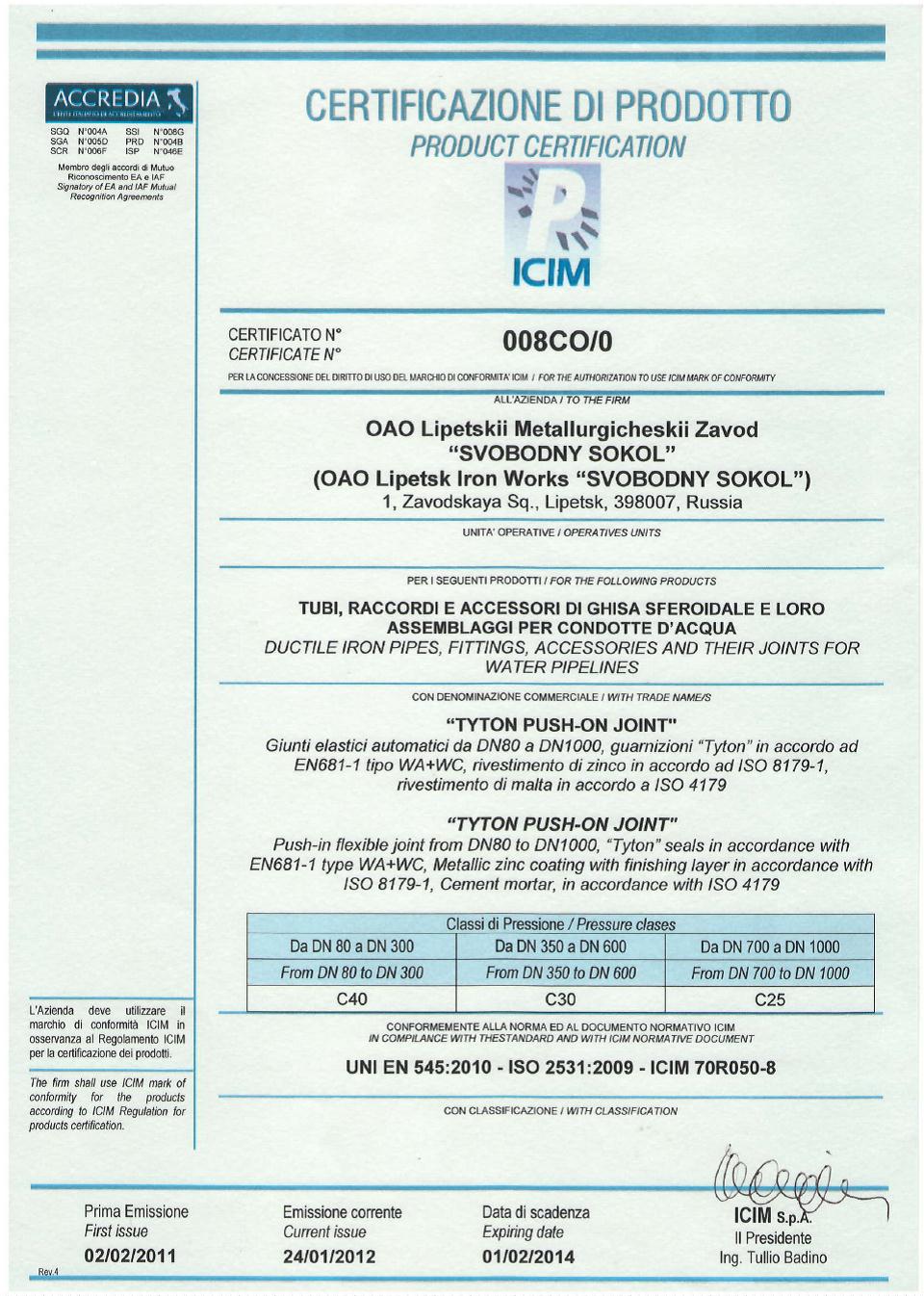

All production has been certified according to international and Russian standards ISO 2531, EN 598, EN 545

|

|

|

|

||||

↑ наверх