Pipe Assembling "RJS" Joint

|

1. Spigot cleaning |

|

2. Greasing of the outside surface of the straight pipe end |

|

3. Socket cleaning |

|

4. Inserting the rubber gasket into the socket |

|

5. Greasing the inner surface of the rubber gasket |

|

6. Connecting the pipes and inserting stoppers |

|

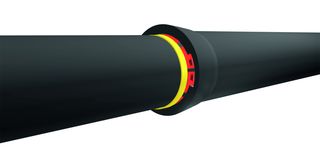

7. Fixation stoppers with metal tape |

Informational letter

about “RJ” joint capabilities manufactured by

Lipetsk Pipe Company "Svobodny Sokol”

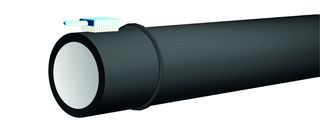

«RJ» Joint – VRS (pic. 1) and “TYTON” (pic.2) abutting push-in joint with rubber sealing ring.

|

|

|

|

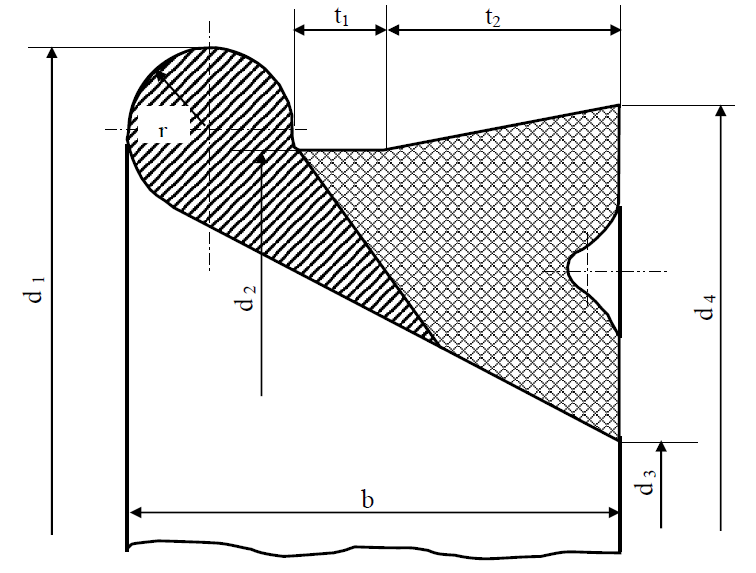

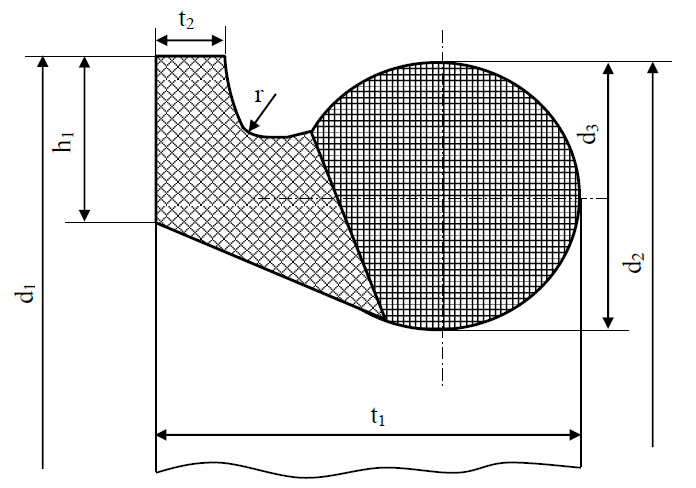

Pic. 1. VRS gasket |

Pic. 2. TYTON gasket |

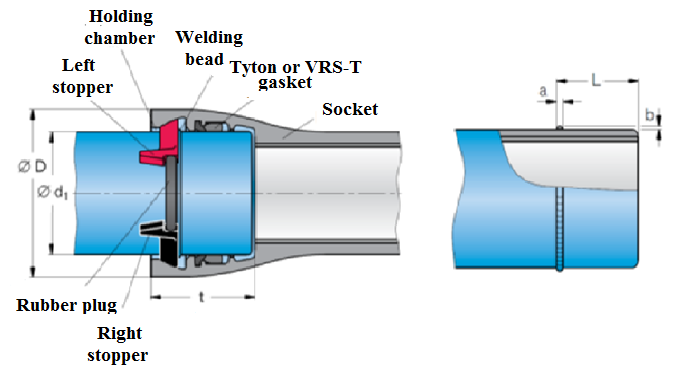

«RJ» joint provides failure of spontaneous pipe disjunction while pipeline operation in difficult terrains, in places of danger of soil precipitation and under shock loads in earthquake-prone areas with seismic activity stability up to 9 points. The welding bead on the pipe end and two stoppers that are inserted into the pipe recess after the joining the pipes secured by a locking wire or rubber retainer, do not allow to break the connection.

This is especially important while installing pipelines in unstable soils, in mountainous terrain and in the vertical position of pipes. Also, the “RJ” joint is used for laying pipelines by the method of horizontal directional drilling.

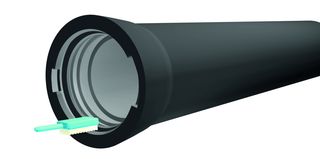

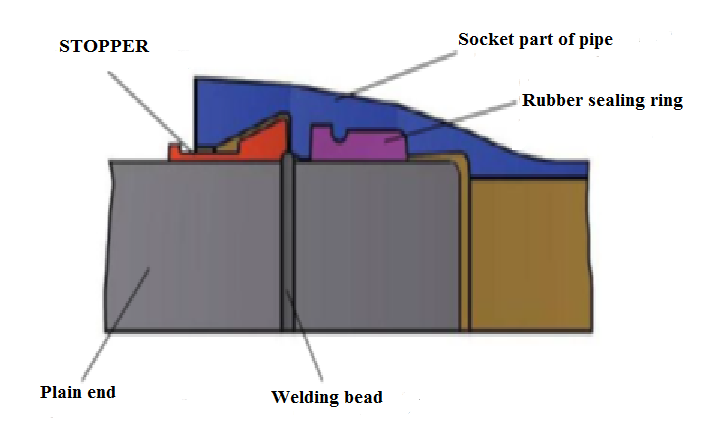

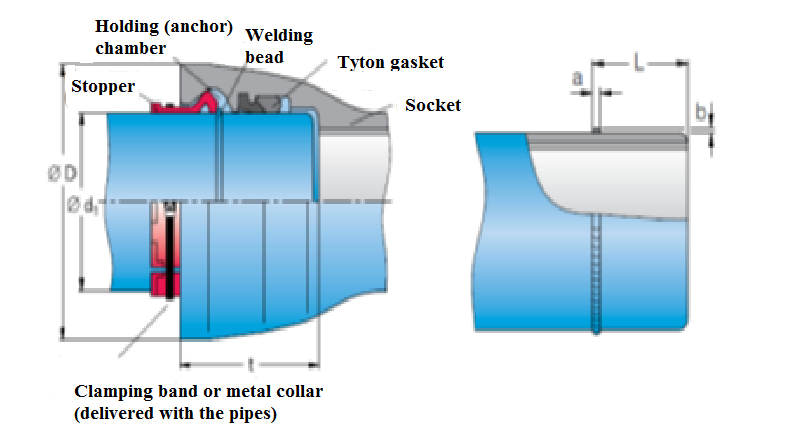

The “RJS” joint - abutting push-in joint with rubber sealing ring “Tyton” type (pic.2). It is an "RJ" joint analogue. This joint is used when laying pipelines of large diameter DN 600-1000 mm, it provides a locking ring on the socket surface with the help of stoppers which are inserted into the pipe recess after the joining the pipes and additionally pulled together by a fixing flexible steel tape H-0.8 × 20 (GOST 3560).

The “RJ” and “RJS” joints are not rigid and allow the connected pipes to deviate by an angle of 1.5 to 5 ° depending on the pipes diameter while maintaining complete tightness of the joint.

Scope of application - cold water supply, heat supply system, sewerage.

The design of the RJ joint (trademark Lipetsk Pipe Company “Svobodny Sokol”) corresponds to the design of the VRS - Tiroflex joint and was transferred to the Svobodny Sokol factory for production by Tiroler Rohren und Metallwerke Aktiengesellschaft on March 24th, 1982, contract No. 7321 / 018202- 01 under license agreement No. 73-21-01-82-022-02.

The design of the “RJS” joint (Pic. 4) was developed (patent of Lipetsk Pipe Company “Svobodny Sokol” ”No. 2472056 dd 01/10/2013) for push-in joint distribution of socket pipes, including large-diameter pipes. Abutting push-in joint has passed all the necessary tests and is certified by ICIM (Italy) and DVGW (Germany) and this joint outperforms the “BLS” (TRM), “Universal Ve” (PAM) joints with the help of smooth stoppers joining in the socket part of pipes.

Pic.3 “VRS-T” and “RJ” push-in joint

Table 1. Size comparison of “VRS-T” (TRM) and “RJ” (Lipetsk Pipe Company “Svobodny Sokol”) pipe joints

|

DN |

TRM size, mm |

Svobodny Sokol size, mm |

||||||||||

|

d1 |

D |

t |

L |

a |

b |

d1 |

D |

t* |

L |

a |

b |

|

|

80 |

98 |

156 |

127 |

86 |

8 |

5 |

98 |

156 |

127 127 |

86 |

8 |

5 |

|

100 |

118 |

182 |

135 |

91 |

8 |

5 |

118 |

176 |

133 135 |

91 |

8 |

5 |

|

125 |

144 |

206 |

143 |

96 |

8 |

5 |

144 |

205 |

139 143 |

96 |

8 |

5 |

|

150 |

170 |

239 |

150 |

101 |

8 |

5 |

170 |

230 |

144 150 |

101 |

8 |

5 |

|

200 |

222 |

293 |

160 |

106 |

9 |

5,5 |

222 |

288 |

155 160 |

106 |

9 |

9 |

|

250 |

274 |

357 |

165 |

106 |

9 |

5,5 |

274 |

346 |

165 165 |

106 |

9 |

9 |

|

300 |

326 |

410 |

170 |

106 |

9 |

5,5 |

326 |

402 |

175 170 |

106 |

9 |

9 |

|

400 |

429 |

521 |

190 |

115 |

10 |

6 |

429 |

513 |

185 190 |

115 |

10 |

10 |

|

500 |

532 |

636 |

200 |

120 |

10 |

6 |

532 |

618 |

200 200 |

120 |

10 |

10 |

|

* - In column t, the upper digits - the length of the socket of the TYTON joint with the rubber sealing ring, the lower digits - the VRS joint with the rubber sealing ring. |

||||||||||||

Pic. 4 “RJS” push-in joint

Pic.5 “BLS” push-in joint

Table 2. Size comparison of “BLS” (TRM) and “RJS” (Lipetsk Pipe Company “Svobodny Sokol”) joints

|

DN |

TRM size, mm |

Svobodny Sokol size, mm |

||||||||||

|

d1 |

D |

t |

L |

a |

b |

d1 |

D |

t* |

L |

a |

b |

|

|

600 |

635 |

732 |

175 |

116 |

9 |

6 |

635 |

729 |

200 |

120 |

11 |

7 |

|

700 |

738 |

849 |

197 |

134 |

9 |

6 |

738 |

848 |

235 |

150 |

11 |

7 |

|

800 |

842 |

960 |

209 |

143 |

9 |

6 |

842 |

960 |

245 |

160 |

11 |

7 |

|

900 |

945 |

1073 |

221 |

149 |

9 |

6 |

945 |

1060 |

260 |

175 |

11 |

7,5 |

|

1000 |

1048 |

1188 |

233 |

159 |

9 |

6 |

1048 |

1164 |

270 |

185 |

11 |

7,5 |

↑ наверх