Energy Efficiency

Inside cement mortar lining of the ductile iron pipes doesn't only ensure observation of the hygienic requirements at potable water transportation, but also improves the hydraulic propetries of the ductile iron pipelines.

Roughness factor (according to COLEBROOK formula) of the inner surface of the ductile iron pipe with inside cement-mortar lining is K - 0,03 for every single pipe. It is recommended to take K - 0,1 for DN 80-250 mm.; K - 0,08 for DN 300-700 mm.; K - 0, 05 for DN 700-1000 mm. for calculations when deigning pipeline systems out of ductile iron so that all friction losses in the assembled pipeline system are considered. that means that ductile iron pipes with inside cement-mortar lining permit to reduce hydraulic losses through friction in the pipeline to a considerable extent and correspond to all the modern energy conservation requirements.

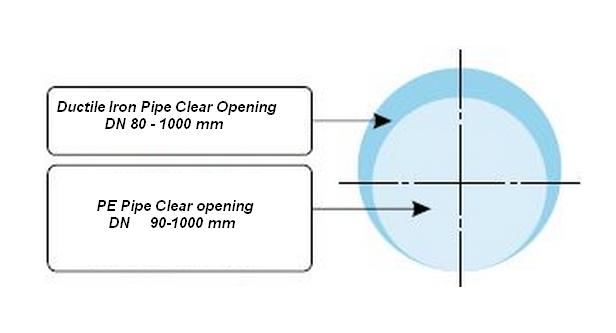

Besides, big flow section of ductile iron pipes compared to polyethylene pipes (with the equal value of nominal bore DN), makes possible a considerable pumping cost reduction of the transported liquid.

The clear opening comparison between ductile iron and polyethylene pipes

DN, мм |

Ductile Iron pipes Svobodny Sokol, Technical specifications1461-037-50254094-2008 |

Polyethylene Pipes PE-100 SDR 17, ALL Union State Standard 18599-2001 |

Ratio of ductile iron pipe clear opening to PE clear opening | ||||||

|

External diameter, mm |

Wall thickness with cement-mortar lining, mm |

Internal diametr, mm |

Passage area, sq. mm |

External diamener, mm |

Wall thickness, mm |

Internal diameter, mm |

Passage area, sq. mm |

||

| 80 | 98 | 9,0 | 80,0 | 5024 | 90 | 5,4 | 79,2 | 4924 | 1,02 |

| 100 | 118 | 9,0 | 100,0 | 7850 | 110 | 6,6 | 96,80 | 7356 | 1,07 |

| 125 | 144 | 9,0 | 126,0 | 12346 | 140 | 8,3 | 123,40 | 11954 | 1,04 |

| 150 | 170 | 9,0 | 152,0 | 18137 | 160 | 9,5 | 141,00 | 15607 | 1,16 |

| 200 | 222 | 9,3 | 203,4 | 32477 | 225 | 13,4 | 198,20 | 30837 | 1,05 |

| 250 | 274 | 9,8 | 254,4 | 50805 | 280 | 16,6 | 246,80 | 47815 | 1,06 |

| 300 | 326 | 10,2 | 305,6 | 73312 | 355 | 21,1 | 312,80 | 76807 | 0,95 |

| 350 | 378 | 12,7 | 352,6 | 97597 | 400 | 23,7 | 352,60 | 97597 | 1,00 |

| 400 | 429 | 13,1 | 402,8 | 127365 | 450 | 26,7 | 396,60 | 123474 | 1,03 |

| 500 | 532 | 14,0 | 504,0 | 199403 | 560 | 33,2 | 493,60 | 191258 | 1,04 |

| 600 | 635 | 14,9 | 605,2 | 287520 | 630 | 37,4 | 555,20 | 241974 | 1,19 |

| 700 | 738 | 16,8 | 704,4 | 389501 | 710 | 42,1 | 625,80 | 307426 | 1,27 |

| 800 | 842 | 17,7 | 806,6 | 510724 | 800 | 47,4 | 705,20 | 390386 | 1,31 |

| 900 | 945 | 18,6 | 907,8 | 646919 | 900 | 53,3 | 793,40 | 484145 | 1,31 |

| 1000 | 1048 | 19,5 | 1009,0 | 7991914 | 1000 | 59,3 | 881,40 | 609840 | 1,31 |

Ductile iron pipe and PE pipe clear passage area comparison DN 100 mm

|

a With the same nominal diameter of ductile iron pipe and PE pipe the clear opening of the ductile iron pipe with inside cement-mortar lining is 30 % bigger than polyethylene one. in diameter range 80 - 1000 mm respectively. |

↑ наверх