Ductile Iron Pipe Outside Coating

The outside coating of the ductile iron pipes is apllied in oder to rotect the pipe from corrosion soil agression and the exist ground currents.

A standard zinc covering is an active cause of the galvanic interracting of the zinc-ductile reaction. The defending mechanism has a double effect: when zinc contacts the soil a new layer is formed of the zinc salts. In case of the local damage the layer regenerates.

Depending on the working conditon the outer coating can be applied in different combinations:

- Metal zinc + finishing layer according to ISO 8179-1

- Zinc-alumina + finishing layer according to ISO 8179-1

- Without any or all the coverings according to customer's desire

The outside surface of the ductile iron pipe can be covered with the finishing layer of:

- Paint based on synthetic resin

- Epoxy

- Bituminous paint

The ductile iron pipes' surface is covered with the zinс or zinc-alumina coating in order to protect the pipes laid in the soil from the corrosion influence.

Despite the fact that the zinс is a good protection for the ductile iron the only zinc covering is not enough cause of fast self corrosion and the absence of corrosion products self-attaching. That's why according to ISO 8179 (Part I) "Ductile iron pipes. External zinc-based coating. Metallic zinc with finishing layer" after the first stage zinc covering the must be another one finishing layer made of paint, paint based on synthetic resin or epoxy.

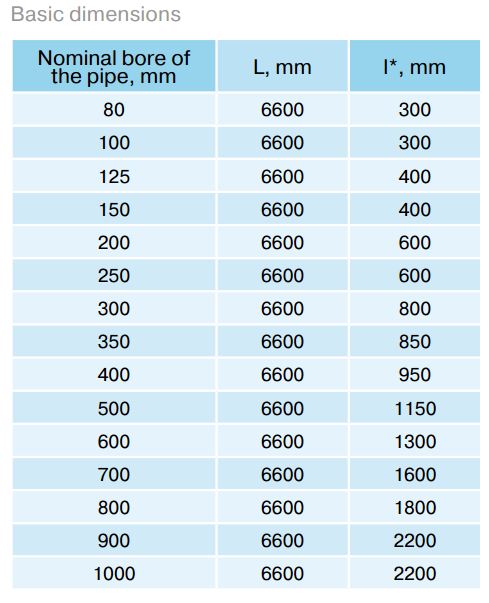

The purpose of the coating application should be considered accordint to the table given below:

|

Soil resistivity, ohm |

Protection covering type |

|

More than 30 |

Bituminous paint or the paint based on synthetical resin |

|

25-30 |

Zinc+ Bituminous paint or the paint based on synthetical resin |

|

15-25 |

Bituminous paint or the paint based on synthetical resin + polyethylene sleeve |

|

Less 15 |

Experiences needed |

In order to protect the pipe better some buildng cimpanies prefer to use a polyethylene sleeve. Polyethylene sleeve is applied additionally to standard external coatings as well as in cases of corrosive soils and ground currents.

Any other type of the outside coating should be consulted with the manufacturer.

↑ наверх