Pipe Assembling

Assembling "Tyton" Assembling "Tyton" |

Assembling "RJ" Assembling "RJ" |

Assembling "RJS" Assembling "RJS" |

Prior to beginning of installation works the inner surface of the pipe and fittings (especially the circular slot for the ring) and the outside surface of the straight end of the pipes and fittings should be cleaned from dirt and objects before putting the pipes to the trench.

Pipes and fittings should be held with special devices when lowering into the trench, so that any damage at the grip spot could be avoided and the item do not hit each other and other objects.

When assembling a pipe with fittings it is necessary to observe the designed contour of the pipeline strictly.

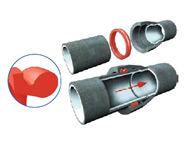

Connection of the pipes and fittings is sealed with a rubber gasket, due to its radial compression in the socket-joint-circular slot.

Insertion depth of the pipe spigot into the socket is marked for "TYTON" joint. "RJ" and "RJS" joints are not marked.

The rubber gasket is inserted in the circular slot; the accuracy position should be checked.

The outside surface of the straight pipe end up to the special mark, and the inner surface of the rubber gasket are greased. It is necessary to avoid grease getting under the outer surface of the rubber gasket

|

The rubber gasket is inserted in the circular slot; the accuracy position should be checked. The outside surface of the straight pipe end up to the special mark, and the inner surface of the rubber gasket are greased. It is necessary to avoid grease getting under the outer surface of the rubber gasket The fitting to be installed is brought to the pipe laid before, centered against the conical surface of the rubber gasket and inserted into the socket up to the special mark with the help of the installation tools pointed rabble (if the pipe diameter is small). When the mounting device force is relieved the mounted fitting goes 5 to 7 mm back. If thefitting goes further, it is necessary to check the distance between the socket and the rubber gasket end, the distance should be constant along with the whole perimeter. Irregular distance indicates that the rubber gasket is pushed out from the socket slot, so it is necessary to repeat the mounting, otherwise the joint will leak during the pressure test. |

|

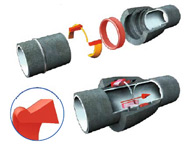

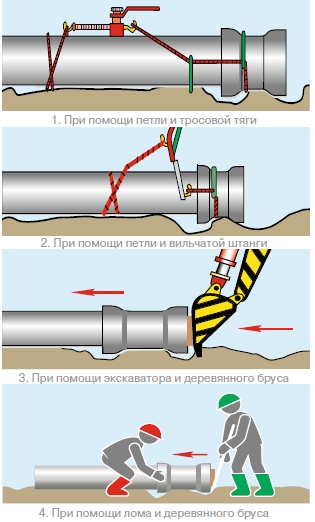

When assembling pipes wtih "RJ" joint after connection it is necessary to:

- Insert the right stopper in the socket slot and move it to the right up as far as it will go.

- Insert the left stopper (with the retaining wire) in the socket slot and move it to the left as far as it will go.

- Bend the retaining wire into the socket slot.

The laid pipeline with the "RJ" joint is capable of axial elongation in the joint due to the technological gap between the welded roll and the lug in the socket part of the pipe.

If elongation has to be avoided by all means it is necessary to stretch the pipeline in the process of laying, section by section, with the help of the rope.

The laid pipes can be disconnected if necessary. First the stoppers are removed then the pipes are pulled out either manually or with the help of a rack jack and a built-up yoke. When reconnecting use new rubber gasket.

Pipes assembling with "RJS" and "RJ" joints is the same.

When pipes are shortened at the site it is necessary to round the straight pipe end or to make a 5x30 facet.

↑ наверх